Covid has been a hard time for the arts, and for artists. For people with compromised immune systems, or who live with people with compromised immune systems, this has been even harder. Life has become one giant exercise in existential fear, as we see policy makers embark on a brave new era in which eugenics, expressed as “the majority of deaths are in people with comorbidities”, is the order of the day.

In this brave new world, public health has been replaced with personal responsibility – not a responsibility to protect your fellow citizen, but rather, a responsibility to protect yourself, and shoulder the sole burden for doing so. Society at large has absolved itself of any obligation to change in order to protect the vulnerable, and the costs that would entail.

The best practices recommended – universal mask-wearing, purifiers for air conditioning systems, working from home, are all being abandoned, seemingly on the basis that if we just “get back to normal”, that life will somehow become normal, in fundamentally abnormal times.

And so, the vulnerable cower in our homes, afraid of the very air outside, knowing that Covid, which hangs in said air exactly as cigarette smoke does, could waft in through an open window, courtesy of a neighbour.

Making art under these circumstances is difficult at best. More so when your process is industrial – metal fabrication, for example.

Prior to Covid, I had worked around a lack of studio space by moving my practice into Virtual Reality – and that worked really well, resulting in the Noosa Mnemonic project with Noosa Library Service. Unfortunately, this was one of the first casualties of Covid, as getting people together in a room, while sharing a device pressed against their faces, wasn’t Covid-safe.

I received an Arts Qld resilience grant early in Covid, to try to build an accessible storage cabinet within my carport. While the grant was acquitted to the satisfaction of the managing arts organisation, the project ran into the very problems it was trying to solve – I couldn’t build it in the space I had available to build it. To be clear, with an appropriate space to lay out the parts during construction, and leave them laid out over multiple sessions, I could definitely build it. Nothing about the construction is beyond me from a technical perspective, and if my carport was a garage, it would be a solvable problem.

I moved on to attempting to work around this, buying a human-weight-rated folding wheelchair ramp, to allow me to roll my welder, and air compressor up a step and into the townhouse so they can be securely stored indoors when not in use. With this setup, I have endeavoured to continue with preparations for my next series of works – doing small experiments, and learning the wiles of my welder.

This was another learning experience. I’ve been able to reduce the setup and packdown time to fifteen minutes each way. However, that hasn’t solved the fundamental problem – I’m working in a carport open to the communal driveway, and to the street. Therefore, I can’t set a work up, and walk away from it (and thousands of dollars of equipment) for lunch, or to think etc.

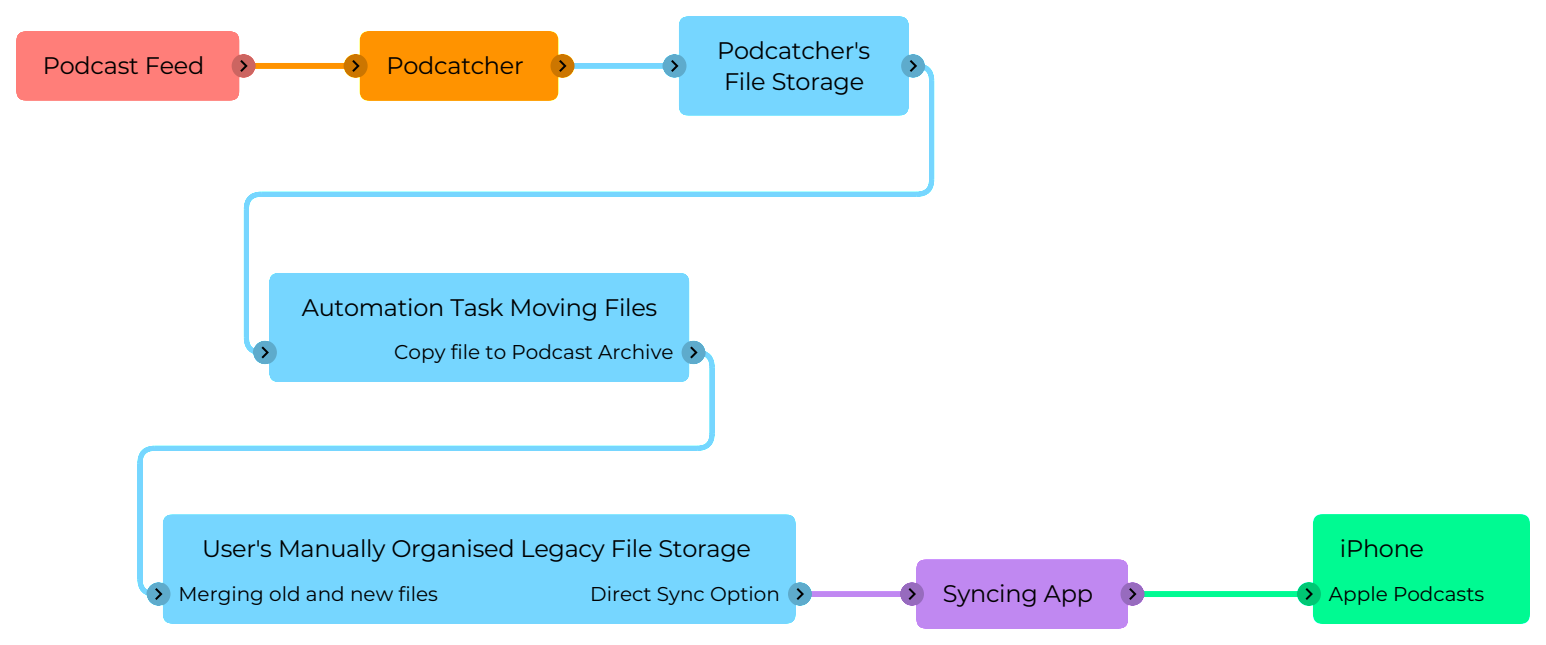

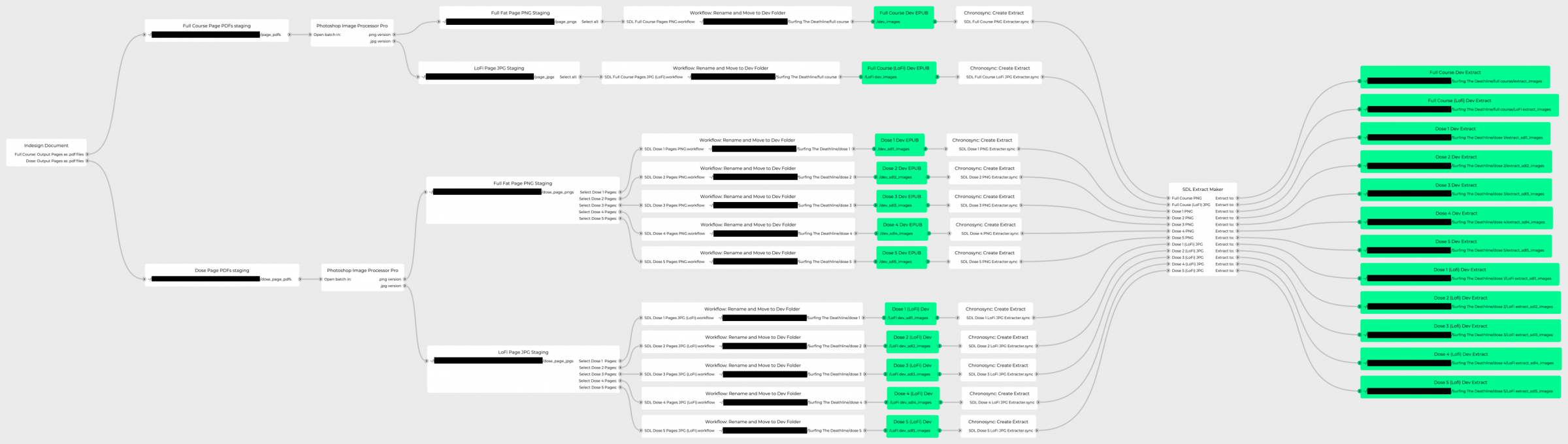

So that’s where we are, in the third year of Covid. My practice is largely revolving around digital processes – rebuilding workflows, and reworking material created before the plague times. In physical works, I’ve mostly been buying and testing gear, for the longer-term goal of getting back into fabrication, once I have a space in which to work. Along with that, has been a months-long process of re-organising my storage facility space, to better arrange all the materials I’ve been accumulating over the years, as well as all the possessions from my old life in Sydney that never found room in what was supposed to be temporary accomodation when I moved to Noosa.

To be fair, there have been some significant achievements during this Covid era. Surfing The Deathline was completed in its final single-volume form – the completion of a project I’ve been working at, on and off, for a little over twenty years.

Alongside that, was making the momentous leap to being fully-independent in selling my eBooks, via a Fastspring-powered general e-commerce store, rather than being reliant on an Apple, Google, or Amazon specific eBook store. Getting this working correctly was a long process, and it’s amazing the sheer amount of time that can seem to vanish on just research, finding out if a thing can be done, then how to do it.

Notwithstanding the time-suck, this is something I’ve been planning towards for a number of years, even prior to Covid. I now have control over the sale of my works – I can set whatever prices I like, and no one can ruin the appearance of the sales experience.

So, this is a roundabout way of saying that while it looks like things have been quiet here (I’m sure everyone’s exhibition records have been pretty sparse for the past couple of years), stuff has been happening, it’s just stuff that stays within the walls of home.